Anchor bolts which are embedded in concrete and used for structural anchorage purposes can assume several forms. Common forms of anchor bolts include right angle bend anchor bolts, swedged rods, and threaded rods (typically with a nut and/or square plate attached to the bottom of the rod). Another common configuration for an anchor bolt is a hex head bolt, where the head is cast into the concrete foundation and the threads project from the concrete. The forged head prevents the hex bolt from pulling out of the foundation.

Almost all imported A307 grade A fasteners will not meet the F1554 grade 36 specification, although they are very similar. Many imported A307 grade A fasteners have no traceability and are only available with a certificate of conformance that contains no chemistry or mechanical property information. When mill test reports are present for imported A307 grade A hex bolts, they are often lacking data that will allow these bolts to be cross-certified to the F1554 grade 36 specification. The F1554 grade 36 specification requires that the bolts meet specific mechanical requirements including tensile strength, yield strength, elongation, and reduction of area. Since the A307 grade A specification does not possess a requirement for yield strength and elongation, these values are rarely reported on the mill test reports. Additionally, since most imported A307 Grade A hex bolts are tested full size, the elongation requirement is waived. In order to cross-certify imported A307 grade A hex bolts to F1554 grade 36, elongation, reduction of area, and yield strength testing must have been performed, the results must be included on the test reports, and the values must fall within the parameters of the F1554 grade 36 specification. Mild steel hex bolts are rarely, if ever, accompanied by test reports that verify all of the mechanical properties of the F1554 grade 36 specification will be met. Unless hex bolts are specifically manufactured and tested to the requirements of F1554 grade 36, they will undoubtedly not be accompanied by the correct certification documents with the additional requirements stated in the chart below.

Mechanical Properties: ASTM A307 grade A vs. F1554 Grade 36

| Grade Marking | Specification | Material and Treatment | Nominal Size (In.) | Mechanical Properties | Hardness Rockwell | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| Proof Load Min (ksi) | Yield Strength Min (ksi) | Tensile Strength Min (ksi) | Elong % Min [9] | RA % Min [10] | Min | Max | ||||

|

A307 Grade A | Low or Medium Carbon Steel | 1⁄4” – 4″ | – | – | 60 | 18 | – | B69 | B100 |

One End Blue One End Blue |

F1554 Grade 36 | Low or Medium Carbon Steel | 1⁄2” – 4″ | – | 36 | 58 min 80 max |

23 | 40 | – | – |

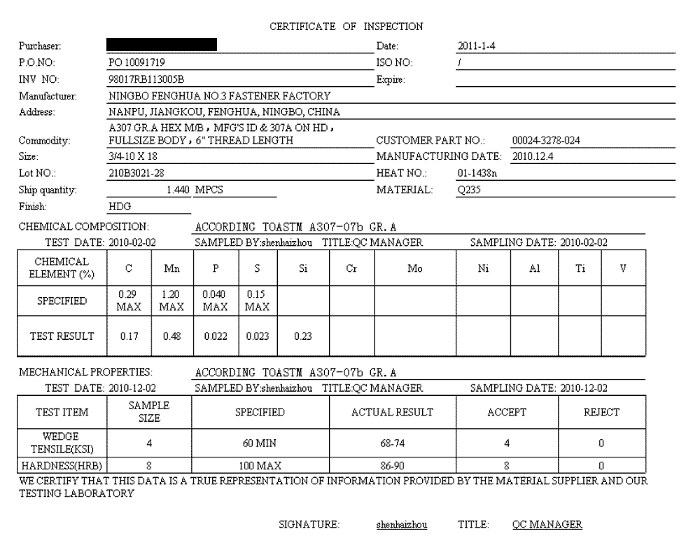

Take a look at the mill test reports for these ¾” x 18” imported hex bolts that are manufactured in China. These hex bolts are manufactured to meet the requirements of A307 grade A. As you can see, the tensile strength of the four samples ranges from 68 ksi – 74 ksi. These values exceed the minimum requirement for A307 grade A and fall between the range required by F1554 grade 36. However, these test reports do not show a yield strength value since this test is not required for A307 grade A. Additionally, elongation and reduction of area values are also absent from these test reports. Since the F1554 grade 36 specification requires all three of these tests to be performed, this particular A307 grade A hex bolt cannot be cross-certified to F1554 grade 36.

Like many other fastener companies, Portland Bolt stocks imported A307 grade A hex bolts, and ours won’t meet the requirements of F1554 grade 36 either. However, we do manufacture F1554 grade 36 hex bolts and stock numerous commonly used sizes that are produced right here in our manufacturing facility in Portland, Oregon.

Like many other fastener companies, Portland Bolt stocks imported A307 grade A hex bolts, and ours won’t meet the requirements of F1554 grade 36 either. However, we do manufacture F1554 grade 36 hex bolts and stock numerous commonly used sizes that are produced right here in our manufacturing facility in Portland, Oregon.

So what should you do if a fastener supplier tells you that they have hex bolts in stock that conform to the requirements of F1554 grade 36?

The first thing to do is question this claim. Although these specifications are similar, they are by no means the same. This is a vital issue since installing imported A307 grade A hex bolts instead of F1554 grade 36 hex bolt can present significant liability issues. By this same standard, we would caution you against allowing a fastener company to substitute a threaded rod with a nut for a true headed bolt. For more information on exposing your company to liability issues by installing the wrong product, read this FAQ.

Although these specifications are similar, they are by no means the same.

It is commonplace in our industry for a bolt supplier to substitute A307 grade A hex bolts when F1554 grade 36 hex bolts are required. Why is this done? There are many reasons ranging from a salesperson’s desire to close a sale and collect their commission with a similar product in stock, to simply not understanding the technical differences between the two specifications. Our suggestion would be to have a copy of the mill test reports sent to you prior to ordering the bolts. If your supplier indeed stocks F1554 grade 36 hex bolts, they will be able to supply you with documentation specifying the chemical and physical properties of the bolts you will be buying. Simply take the test reports and find the yield strength, elongation, and reduction of area values. If any are missing, and this will likely be the case, the bolts will not meet the requirements of F1554 grade 36. Because the substitution of A307 grade A hex bolts for F1554 grade 36 hex bolts is so commonplace, it is up to you to protect your company from a potential lawsuit and verify for yourself that the F1554 grade 36 hex bolts you are buying meet the requirements of the specification.

Portland Bolt employs a team of knowledgeable inside salespeople / estimators who will assist you with every aspect of the fastener purchasing process. We will ensure that you receive bolts that meet the requirements of the specification. Our salespeople are not paid on commission, and we work together as a team to service our customers and make sure you receive the product that was specified by the engineer. We will never substitute a product of a different grade or configuration in order to save a little time or a little money; that tactic would expose both your company and Portland Bolt to a tremendous amount of liability. We are experts on construction fasteners. If you ever have a technical question or feel the need to verify information provided to you by another source, please give us a call.

What Strength of grade covers ASTM A307 GRADE A

Is it 4.8 or 8.8

@Steve- While not exact, 4.8 would be the closer of those to A307A.

Great thread. Could you please explain why A307 is called machine bolt??

Thanks

@Shamsul- Hex bolts are sometimes called machine bolts because they are many times used in machinery.

My supplier has supplied anchor bolts of G40.21 44W instead of ASTM 307, what you suggests?

Thanks

@Kamran- CSA G40.21 44W is a raw steel standard, whereas ASTM A307 is a finished bolt standard. It would be possible to make A307 bolts from 44W steel, but you’d have to look at the MTRs and make sure the chemical and mechanical requirements are met.

Would Portland Bolt be able to make an F1554-55 anchor bolt that could also be used as an A307 Hex Bolt? I have a customer that would use these bolts for 2 different applications and is trying to kill 2 birds with 1 stone. In other words, could an A307 be manufactured to F1554-55 spec’s and still be called an A307 bolt?

@Joshua- Yes, a F1554g55 bolt could be manufactured to also meet all the requirements of both F1554g55 and A307A.

How would you mark the head?

@Boyd- The head is marked as part of the heading/manufacturing process with a steel die.

I have bolts that have 3 small triangles on them and the letters CYI, these bolts have 3 hash marks on them also. Can you tell me what the CYI means? They are shiney, aren’t most hardened bolts not shiney? These are being used on flanges for HTHW buy a contractor, we want to make sure they are ok.

@Chuck Paffie – The CYI is the manufacturer’s identification, in this case I believe a manufacturer from China. The three hash marks indicate the the bolt is a SAE J429 grade 5. There shouldn’t be a difference in shininess between hardened and non hardened, several variables can affect the appearance. The triangles I am not familiar with. If you’d like to send in a photo, we’d be happy to look at it.