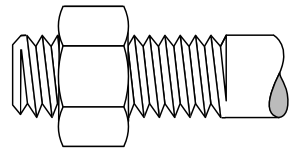

This is a difficult question to answer. Depending on your application, the answer could be anywhere from 1/2 engagement, up to having two full threads extend beyond the nut. Look at these conflicting answers found in four separate technical publications.

This is a difficult question to answer. Depending on your application, the answer could be anywhere from 1/2 engagement, up to having two full threads extend beyond the nut. Look at these conflicting answers found in four separate technical publications.

- Federal Highway Administration, “Guidelines for the Installation, Inspection, Maintenance and Repair of Structural Supports for Highway Signs, Luminaires and Traffic Signals.” Section 16.3.1.2 Anchor Rods

- “Many times the rod is not long enough and the anchor nut is not fully engaged. This in itself is not a serious deficiency as long as at least three quarters of the nut is engaged.”

- https://www.fhwa.dot.gov/bridge/signinspection.pdf

- Industrial Fasteners Institute, Joe Greenslade, Director of Engineering Technology.

- “How Many Threads Should Be Beyond The Nut?. The answer is: A minimum of two thread pitches should extend beyond the top surface of the nut.”

- RCSC (Research Council for Structural Connections) Specification for Structural Joints Using ASTM A325 or A490 Bolts 2.3.2. Geometry

- “Heavy-hex structural bolt dimensions shall meet the requirements of ANSI/ASME B18.2.6. The bolt length used shall be such that the end of the bolt extends beyond or is at least flush with the outer face of the nut when properly installed.”

- https://www.boltcouncil.org/files/2009RCSCSpecification.pdf

- AISC Design Guide1 Page 10 Section 2.11.3

- “Often, when the anchor rod is short, it may be possible to partially engage the nut. A conservative estimate of the resulting nut strength can be made based on the percentage of threads engaged, as long as at least half of the threads in the nut are engaged.”

- https://www.aisc.org/store/p-1749-design-guide-1-base-plate-and-anchor-rod-design-second.aspx

- AISC Steel Construction Manual, 13th Edition, Section 14-10

- “Adequate thread engagement for anchor rods is identical to the condition described in the RCSC Specification as adequate for steel to steel structural joints using high strength bolts: having the end of the [anchor rod] flush with or outside the face of the nut”

So we are left a little confused…..which is it? The answer is, it depends. All joints are not created equal. Tightening an A325 structural bolt on a bridge may have different requirements than tightening the nut on an anchor bolt for a traffic signal pole. Some screw and bolt specifications allow for one or more incomplete threads on the point end of the bolt to allow for easier mating, while others do not. Structural bolts like A325s or A490s have a limited thread length, so having too many threads stick out may mean that the nut is engaging into the thread run out and may not be able to develop the full strength needed. Conversely, not enough stick out may leave threads exposed in the shear plane, which may not be desirable. The safest answer is to consult with the project engineer on your job, to assure all variables that are specific to your job are taken into consideration.

My take is capacity is based on shear capacity of the threads themselves. Once threads are all engaged, it has met it’s requirement.

If you look at a nut closely, the threads stop subset from the surface. The inside of the hole of the nut is beveled on both sides. If you look at a bolt closely, you will see that the thread height diminishes as it gets closer to the end of the bolt. Now thread the nut onto the bolt until you see a fully formed bolt thread engages with a fully formed nut thread and you will see a flush surface. Bingo!

To those who count on extra thread for a torqued bolt potentially coming loose, impossible if the torque was done properly.

It is acceptable to use high strength bolt a490 it is flush with the outer face of the nut for bridge

steel girder joint connection.

@Grego- I believe a flush nut is acceptable per the AISC and RCSC. That said the EOR should probably be made aware and should be allowed to sign off if there is some question.

How many threads on 1 1/4 inch diameter coil rod are necessary to lift a 5 X 10 road plate that is 1 inch thick and weighs a couple thousand pounds. We had a failure and determined that the worker had not screwed in the lifting eye flush but backed it off a half turn after turning it flush. After review we found that this was common among the workforce. The lifting ring has 1 inch of rod sticking out beyond the base plate. Thread is 3.5 coils per inch. The bottom two and a half threads near the end of the rod stripped.

Thanks,

Bob Kelley

@Bob- Apologies, we do not have any engineers on staff and so are unable to help with this calculation.

This is great information. Rules of thumb, like for inspection, is a prescriptive approach and for new construction this is best. But sometimes the prescriptive rule cannot be met (new light pole with thicker base plate on an existing pier for example) and we need to be able to sharpen the pencil and calculate what we really need for those few exceptions.

Thanks for info.. it’s really useful for us.