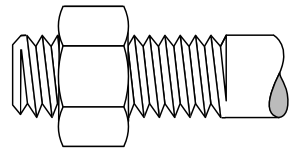

This is a difficult question to answer. Depending on your application, the answer could be anywhere from 1/2 engagement, up to having two full threads extend beyond the nut. Look at these conflicting answers found in four separate technical publications.

This is a difficult question to answer. Depending on your application, the answer could be anywhere from 1/2 engagement, up to having two full threads extend beyond the nut. Look at these conflicting answers found in four separate technical publications.

- Federal Highway Administration, “Guidelines for the Installation, Inspection, Maintenance and Repair of Structural Supports for Highway Signs, Luminaires and Traffic Signals.” Section 16.3.1.2 Anchor Rods

- “Many times the rod is not long enough and the anchor nut is not fully engaged. This in itself is not a serious deficiency as long as at least three quarters of the nut is engaged.”

- https://www.fhwa.dot.gov/bridge/signinspection.pdf

- Industrial Fasteners Institute, Joe Greenslade, Director of Engineering Technology.

- “How Many Threads Should Be Beyond The Nut?. The answer is: A minimum of two thread pitches should extend beyond the top surface of the nut.”

- RCSC (Research Council for Structural Connections) Specification for Structural Joints Using ASTM A325 or A490 Bolts 2.3.2. Geometry

- “Heavy-hex structural bolt dimensions shall meet the requirements of ANSI/ASME B18.2.6. The bolt length used shall be such that the end of the bolt extends beyond or is at least flush with the outer face of the nut when properly installed.”

- https://www.boltcouncil.org/files/2009RCSCSpecification.pdf

- AISC Design Guide1 Page 10 Section 2.11.3

- “Often, when the anchor rod is short, it may be possible to partially engage the nut. A conservative estimate of the resulting nut strength can be made based on the percentage of threads engaged, as long as at least half of the threads in the nut are engaged.”

- https://www.aisc.org/store/p-1749-design-guide-1-base-plate-and-anchor-rod-design-second.aspx

- AISC Steel Construction Manual, 13th Edition, Section 14-10

- “Adequate thread engagement for anchor rods is identical to the condition described in the RCSC Specification as adequate for steel to steel structural joints using high strength bolts: having the end of the [anchor rod] flush with or outside the face of the nut”

So we are left a little confused…..which is it? The answer is, it depends. All joints are not created equal. Tightening an A325 structural bolt on a bridge may have different requirements than tightening the nut on an anchor bolt for a traffic signal pole. Some screw and bolt specifications allow for one or more incomplete threads on the point end of the bolt to allow for easier mating, while others do not. Structural bolts like A325s or A490s have a limited thread length, so having too many threads stick out may mean that the nut is engaging into the thread run out and may not be able to develop the full strength needed. Conversely, not enough stick out may leave threads exposed in the shear plane, which may not be desirable. The safest answer is to consult with the project engineer on your job, to assure all variables that are specific to your job are taken into consideration.

1. I always check the thread engagement at the shank since structural bolts have random thread lengths. Some of the bolts barely have any thread projecting out the top in order to work without “bottoming out”.

2. If building machinery, use lock washers and flat washers on slots with grade 5 bolts, not A325 bolts. This is our practice.

ASME B31.3, 335.2.3, states:

Bolts should extend completely

through their nuts. Any which fail to do so are

considered acceptably engaged if the lack of complete

engagement is not more than one thread.

I would think that this requirement is dependent on the nature of the objects being fastened together. For example: a industrial machine that will vibrate while in operation could need to have threads extending past the nut to minimize the risk of the nut loosening and failing/coming off.

Just a thought.

@Taylor – Yes, exactly. Every application will have its own nuances that may require more or less thread engagement.

Wow, this is in every respect what I needed to know.

There’s nothing like the releif of finding what you’re looking for.