Is it possible to put threads on rebar?

The answer is yes, however, there are several issues to consider to avoid liability. For this discussion, we will assume a requirement for threaded rebar as follows:

#8 x 48″ long A615 grade 60 rebar with 8″ thread one end.

What is rebar?

Rebar is short for “reinforcing bar” and often used in concrete foundations to strengthen the concrete. It is held in place by systematic ridges or deformations in its surface that allow the concrete to “grip” the bar better than plain round bar. These deformations are a great asset in the masonry applications, but hinder the usefulness of rebar as a threaded fastener.

Rebar gauges (diameter of the bar) are measured in eighths of an inch. For example, #8 rebar is essentially 1″ diameter (8 x 1/8″ = 8/8″ or 1″).

Cut Threading Rebar

Why can’t you just put threads on rebar?

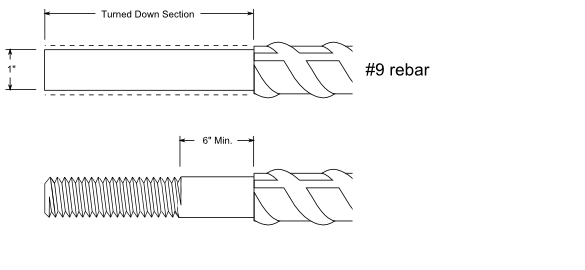

Rebar cannot simply be cut threaded to the nominal diameter. This is due to the diameter difference between the major diameter of UNC threads and the diameter inside the deformations. The diameter inside the deformations is less than the minimum allowable major thread diameter. This will lead to incomplete threads and the liability that comes with product not meeting dimensional tolerances. As an example, the diameter on #8 rebar between the deformations is .960 and the minimum allowed major diameter on 1″ threads is .9755.

How to properly cut thread rebar

The only way to correctly thread rebar is by turning down, or milling the end of the rod so that it is the proper size and shape to be threaded. This is done by removing the outer layer of the bar until the diameter is equal to the deepest deformation on the bar, leaving a smooth surface to thread. The smaller diameter of the threaded portion means that a larger size of rebar will have to be used and turned down in order to have threads that are the correct nominal diameter. If we go back to our example rebar above, we would need to use #9 rebar, instead of #8 in order to have proper 1″ UNC threads.

Things to keep in mind when ordering threaded rebar

In cases where plans call for threaded rebar, it is essential that the engineer or detailer specify the diameter of thread needed on the bar, since cut threading a #8 rebar will not result in a complete 1″ UNC thread. When thread type is not specified or ambiguous, Portland Bolt makes the assumption that the design requires a 1″ thread and when cut threading, will use a #10 bar to produce a fully functional 1″ – 8 threads per inch Unified National Coarse thread as opposed to cut threading a #8 bar which results in a 3/4″ – 10 thread per inch finished product.

Roll Threading Rebar

As opposed to cut threading, the threads on rebar can also be produced through a roll threading process. For the differences and limitations of roll threading versus cut threading, refer to our FAQ discussing roll threading versus cut threading. Keep in mind that roll threading equipment is limited in the marketplace and many companies that produce threaded rebar will not have the equipment available to roll threads. Most machine shops and smaller scale bolt manufacturing companies only have equipment that is capable of cut threading.

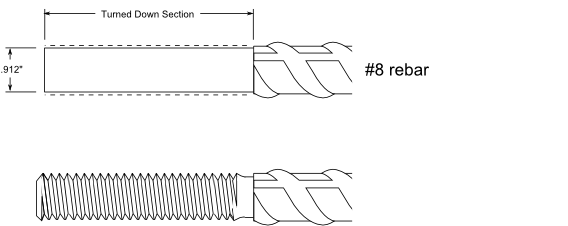

Unlike the cut thread example above, rebar can be turned to the pitch diameter (.912″ in our example using #8 rebar) and rolled back up to produce a fully functional, dimensionally correct 1″- 8 UNC thread. Since some roll threading equipment has diameter and length limitations, rolling threads on rebar is sometimes not possible. Again, the thread dimension in addition to the size of the rebar should be specified.

To specify threaded rebar properly, our inquiry for this example should read as follows:

#8 (1″-8 UNC) x 48″ long A615 grade 60 rebar with 8″ thread one end.

Using a decent bench grinder to the first 5 or so inches of a 1/2″ piece of rebar is a quite simple way to prepare the rebar for a 1/2″ –13 dye.

When grinding, I focused at first on the two raised sections of the knurling and then I simply spun the bar end as I ground the knurling down about 95%.

I avoided taking it off completely because then I would have no real dimension marker.

The dye worked quite well as I lubed it and on every turn, went back and broke the chip.

I am using these 4ft. sections to hold down guardrail sections I am using as water bars on a pitched gravel driveway.

@Greg- that sounds like a hard way to do it, but I am glad it worked for you.

Hello I want the calculation/ formula to calculate the numbers of threads for notch milling machine it is mentioned as Zp in some manufacturer charts example if my roll diameter is 300 and core diameter for 8mm rebar size is 7.5 and the no of notches is 196 and notch angle is 55 degrees then what will be value of no of threads .Can anyone help

@Gulshan- Apologies, but we are unable to help with this.

Dear Sir,

Why threds get brocken while cold forging on 32mm TMT bar. we are using cold forging M/c.

It get puff up after forging and then it get put in to thred dia, which results either steel cracking or steel threads.

@Aman- Apologies, we are unable to help with this issue.

When turning down rebar, what would cause the front of the bar to be larger than the back of the bar? It is a very consistent tapper. Front being the begin of the turn and end being closer to the collar.

@Matt – Apologies but we are not sure what you mean. When we turn down rebar to thread it, there is no taper.

Any reviews on Chinese made rebar threaded connectors used in concrete.

@Sarala- we do not have an experience supplying off shore rebar.

Threaded M 20 bolt broken flash with concrete need to tread bolt

open concrete around the bolt to have space to thread the shaft inside concrete block

@Pierre- There are a few options for repairing that broken bolt, from chiseling out the concrete and adding an extension, to drilling a hole for an epoxy anchor. Your project engineer can help you determine the best alternative.

Do the mechanical properties of the rebar steel require a special longer nut to full develop the capacity of rebar with a threaded connection?

@Troy- There are many issues with threading rebar, as outlined in this FAQ. However, once threaded, a standard nut will be sufficient.

What is the reason for 6″ (min) length plain turned down section in cut threaded rebar ?

@Jean- We need the 6″ in order for the cutting head to be able to clear the shank. Without that 6″, there is not enough clearance in our threading machines.

Dear sir, now my project is condominium 22 floor , can i use this method to replace the lapping Deform-bars?

@Pak- You will need to consult the project engineer for this question, we are unable to answer.

Do you have any international test method for tesnsile load test for threaded rebar

@Nishad- ASTM F606 discusses the testing of general threaded fasteners, and ASTM A370 covers testing for steel bars. However we are not aware of any specific testing requirements for threaded rebar beyond the two standards above.

Is it possible to make such threading on notch milling machine normally used in making notches on rebar from 8mm to 40mm in rolling mills?.

Please provide information.

@Gulshan – The issue is not the ability to cut threads, the issue is that the rebar dimensions to not lend themselves well to allowing complete threads. You have to go down one thread size in order to form complete threads. For example on #8 rebar, we can only cut 7/8-9 threads because the minor diameter of the bar is less than 1″ – 1-8 threads will be incomplete and have flat spots.

Does any one tell if there is any ASTM standard covering threading of rebar please? or maybe a ISO standard

@Mark – Not no our knowledge, no. Threading of rebar is quite common, but none of the ASTM standards that cover rebar mention threading, and none of the threaded fastener standards mention rebar. We are not familiar enough with the various ISO standards to know if anything exists there.

This is good info for all contractors. My brother works in new construction, and some of his employees could benefit from the knowledge in this article and on your site. I’ll pass it along to him.

Mark

webmaster – https://charlotte-golf.com

Do you make a tool to screw them together after you poured one side in

What should the turn down diameter be when you are threading #18 gr75 rebar to 2.25 anchor bolts – 4.5 tpi.

@Brad Blacketer – #18J rebar starts out slightly oversized to allow for it to be turned down to 2-1/4–4-1/2. The only rebar grades to normally come this way are #18J and #14J. Other sizes are not oversized and must be turned all the way down to the next smaller size in order to be threaded.