What information do I need to provide when ordering tie rods or requesting a quotation to ensure that I receive the correct product?

Tie rod assemblies can be very complicated and confusing to someone who does not deal with them on a routine basis. If you are not experienced in dealing with tie rod assemblies, you may not understand all of the necessary information that is required to ensure that you receive the proper components for the tie rods to function correctly and assemble smoothly. The good news is that Portland Bolt’s experienced sales staff is trained to ask all of the questions necessary to ensure you receive the correct components.

Below is a list of information that our estimators will need to know in order to work up an accurate quotation. To save time and ensure an accurate quote, please include this information in your request for quote.

1. Configuration

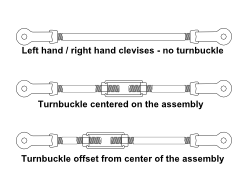

The first basic piece of information required is the configuration of the tie-rod assembly. Tie rods come in three basic configurations:

A. Assemblies consisting of a rod with a left hand threaded clevis on one end and a right hand threaded clevis on the other end.

B. Assemblies with right hand threaded clevises on both ends and a turnbuckle in the center of the assembly.

C. Assemblies with right hand threaded clevises on both ends and a turnbuckle offset from center of the assembly.

2. Rod Diameter

The diameter of the rods will dictate the compatible clevises size(s) as well as the size of the turnbuckle (if required). Some diameters of rod may be utilized with more than one clevis size. In cases like this, we will let you know what the available options are. For instance, 7⁄8” diameter rods could be used with either #21⁄2 or with #3 clevises. In some cases, the rod diameter/clevis size combination will dictate the clevis pin diameter as well. Refer to this Clevis Numbers for Various Rods and Pins chart for more information.

3. Overall Length of the Assembly

In order to calculate the correct length of the rod portion(s) of the tie rod assembly, we will need to know the overall length of the assembly. This dimension is measured from the centerline of the clevis pin on one end of the assembly to the centerline of the clevis pin on the opposite end. This dimension is often called the “pin to pin” dimension or abbreviated further to “P2P” length. The actual rod lengths are frequently detailed on the drawings, however, if rod lengths are not specified, our Tie Rod Calculator will determine these rod lengths for you.

4. Clevis Pin Size

Once the clevis size has been determined (see Step 2 above), the pin size will also need to be determined. Typically, there is a limited range of sizes that the pin must fall within. This allowable range is a function of the clevis number and rod diameter (Tap) combination, which has been calculated such that the clevis and pin will be stronger than the rods of the assembly. The allowable Pin & Tap combinations can be found on our clevis page. In some cases, such as design/build projects or quotes for bidding purposes, we can quote tie rod assemblies without knowing the pin size. In cases like this we will typically quote a pin size that is the same as the rod diameter of the assembly for estimate purposes only. However, in cases like this the purchaser would need to verify the pin size is correct before placing an actual order.

5. Clevis Grip

The grip size is based on the thickness of the plate that will slide in between the “ears” of the clevis and that will receive the clevis pin. The grip size is normally specified as the plate thickness + 1⁄4“, however since the clevis is a forged steel part, there is a limited range to which the clevis ears can be compressed or spread apart to achieve the desired grip. The grip guidelines can be seen on the chart below:

| Clevis Size | # 2 | # 21⁄2 | # 3 | # 31⁄2 | # 4 | # 5 | # 6 | # 7 | # 8 |

|---|---|---|---|---|---|---|---|---|---|

| Min. Grip Size | 3⁄4" | 3⁄4" | 3⁄4" | 7⁄8" | 7⁄8" | 1" | 1" | 1" | 1" |

| Max. Grip Size | 3⁄4" | 11⁄4" | 11⁄2" | 2" | 21⁄4" | 23⁄4" | 31⁄2" | 41⁄2" | 5" |

In some cases, such as design/build projects or quotes for bidding purposes, we can quote tie rod assemblies without knowing the grip size. In cases like this we will quote the clevises as “Grip To Be Determined” or “Grip TBD” for short. However, in cases like this the purchaser would need to determine and specify the clevis grip before placing an actual order.

6. Finish

Finish can greatly affect the lead time and cost of a tie rod assembly. For this reason, our estimator’s will need to know at the time of quote request whether the tie rod assemblies you are after are plain steel, hot-dip galvanized, or stainless steel. In the case of galvanized assemblies, the clevises (and turnbuckles if required) will need to be galvanized and tapped oversize to accept the galvanized threads of the rods. In the case of stainless steel, the rods can be supplied in either Type 304 or Type 316 stainless, however, the clevises and turnbuckles are only available in electropolished Type 316 stainless.

7. Quantity

For each particular configuration of tie-rod assembly, we will need to know how many of that assembly are required. For instance, you may have a requirement for 10 assemblies of 1″ rods and another for 6 assemblies with 11⁄4” rods. We would need to know how many of each type are required. Also, for assemblies with the same rod diameter and the same components, but with different overall “P2P” lengths, we would need to know how many of each length assembly are required.

8. Grade

The vast majority of tie rod assemblies are engineered using mild steel rods. These are typically specified to the raw material grade A36 or the finished rod specification A307 grade A. In rare instances, engineers will design high strength tie rod assemblies using A572 grade 50, A449, or one of several other ASTM grades of high strength rod. In this instance, the engineer will need to determine whether a standard clevises (and turnbuckles) will be strong enough to develop the full strength of the assembly. High strength clevises and turnbuckles are available by special order. When stainless steel rods are required, simply specify type 304 or type 316 stainless steel.

Sample Request

An example request for quote on a tie rod assembly might look like this:

(10) tie-rod assemblies, 1″ Galvanized A307 grade A rods, 168” overall length pin to pin, with turnbuckle in center of each span, #3 clevis on each end with 1″ pin and 1″ grip for 3⁄4” plate.

If you provide us the above information with your inquiry, we will be able to provide you a quote that is accurate, and ultimately, with the tie rod assemblies that will function correctly on your project.

Do you have a minimum order value or quantity? I need two assemblies about 6’ long. Not sure if that would meet your minimum order size.

@Charles- We do not have a minimum order quantity, but as we manufacture everything from scratch, the price for one or two assemblies might be a bit high compared to a larger quantity since there are fixed costs the would only be amortized into fewer assemblies.

Hello I’m in Ontario, Canada, hoping you have a dealer nearby or you could ship to Canada. Thanks!

@Ryan- Thank you for your interest. We do not have any dealers at all, everything comes from our warehouse in Portland OR. We do ship to Canada everyday and would be happy to ship some product your way.

I would like to obtain a quote on the following:

5/8/” diameter x 26’0″ long, black tie rods with threaded ends, and turnbuckle in the center. Ends of bars to be threaded for assembly with a 3″x3″x 7/16″ bearing plate and standard nut. Total quantity needed is 4.

@William- one of our salespeople will contact you shortly.

Hello,

Down here in San Carlos California, This is Mike Zinnanti w/ Lencioni Construction.

We have purchased an Older Building and are in the process of remodeling.

Somewhere along the way, Someone has removed a Tie Rod assembly from one of the Exposed Trusses.

I would like to replace and would like to Send to you photos of the condition, to see if you can Help us out with Parts Needed.

Thanks!

@Mike- One of our salespeople will contact you shortly about this.

I would like a quote on two 3/4″ tie today’s 24′ long each with a left hand and a right hand Clevis and each with a turn buckle in the center and black

@Dustin- One of our salespeople will contact you shortly.

Hi, could I buy just clevises and turnbuckles? If so, what is the cost of them for 1inch rod diameter?

@Loren- We normally only supply clevises and turnbuckles as part of an assembly. One of our salespeople will be contacting you shortly to discuss your needs.

I would like a quote for a tie rod assembly 3/4 dia 11′-6′ long stainless finish 3/4″ pin 6 pcs

4pcs 21′ long

@Brad- One of our salespeople will contact you shortly regarding this.

i would like a quote on the following (3), 3/4″ Tie Rod Assemblies 150″ pin to pin, turnbuckle in the center of each span, #2 1/2 with 3/4″ pin and 3/4″ grip for 3/4″ plate, finish in plain steel.

thanks

@Nate – One of our salespeople will contact you shortly.

Hello, I would like a quote on the following: (4), 3/4″ tie rod assemblies, 168″ overall length pin to pin, with turnbuckle in the center of each span, #2 1/2 with 3/4″ pin and 3/4″ grip for 3/4″ plate, finish in plain steel. Thank you.

@Mark – One of our salespeople will contact you shortly.

Hi

Could you give me a quote on a 7′ tie rod black, with left and right clevises, no turn buckle.

I live in Ottawa, Canada. Do you have a dealer here or close by?

Thanks

Bill

@Bill Weber – Yes, one of our estimators will contact you shortly.