Coupling Nut Thread Engagement

Unfortunately there appears to be no documented information on how much rod engagement into a coupling nut is required to achieve the strength of the rod or bolt being used with it. Coupling nuts are manufactured to the same ASTM specifications as regular hex nuts, and ASME B18.2.2 provides dimensional specifications for coupling nuts. Standard coupling nuts are 3 diameters in length. However, there is no reference to coupling nuts in the actual ASTM A563 or A194 nut specifications.

Unfortunately there appears to be no documented information on how much rod engagement into a coupling nut is required to achieve the strength of the rod or bolt being used with it. Coupling nuts are manufactured to the same ASTM specifications as regular hex nuts, and ASME B18.2.2 provides dimensional specifications for coupling nuts. Standard coupling nuts are 3 diameters in length. However, there is no reference to coupling nuts in the actual ASTM A563 or A194 nut specifications.

Your first step is making sure that the ASTM grade of coupling nut being used with the threaded rod or bolt is the same grade as the recommended grade of nut that would be used with the rod or bolt. For example, ASTM A193 B7 rods or bolts require an ASTM A194 2H heavy hex nut, so if you were to use a coupling nut with an ASTM A193 B7 rod, the grade of coupling nut should also be ASTM A194 2H. Although the amount of thread engagement is not specified, our coupling nut supplier recommends the bolt or rod should be threaded a minimum of one diameter in length into one end of the coupling nut.

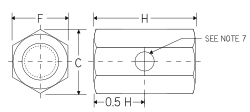

There may be an application which requires that the threaded parts going in each end of the coupling nut are engaged approximately one half of the coupling nut thickness. In this case, a hole may be drilled in the middle of one side of the coupling nut. This aids in the visual inspection to ensure that both rod ends are in fact meeting in the middle, not off center. According to IFI-128, note 7, the hole should be located at mid nut thickness and have a diameter of 0.2 to 0.4 times nominal nut size for sizes 2-1/2″ and smaller. For sizes 2-3/4″ and larger, the hole is 1″. Coupling nuts are manufactured without this hole unless otherwise specified.

As long as the correct grade of coupling nut is used and the bolts or rods are engaged a minimum of one diameter, the bolt should theoretically break before the threads strip. Again, this is only a common rule of thumb and we have no documented specifications that cover this issue. In any situation involving coupling nuts, we would recommend consulting with the engineer of record or a structural engineer to determine the appropriate length of coupling nut and amount of thread engagement required.

Charlie N. Nunez, PE

Dane:

I need to extend 4 – 1″ dia. Galv. anchor bolts with standard threads and would like to use fabricated stand-off, in order to keep the length of the coupler to a minimum. The total length of the stand-off, including the coupler and threaded rod to be 6 1/2″ long. Can you weld a 1″ dia. galvanized threaded rod (ASTM A307) to a 2″ long galvanized coupler, leaving sufficient thread in the un-welded end of the coupler to meet the 1.5 x rod diameter requirement?