Unfortunately there appears to be no documented information on how much rod engagement into a coupling nut is required to achieve the strength of the rod or bolt being used with it. Coupling nuts are manufactured to the same ASTM specifications as regular hex nuts, and ASME B18.2.2 provides dimensional specifications for coupling nuts. Standard coupling nuts are 3 diameters in length. However, there is no reference to coupling nuts in the actual ASTM A563 or A194 nut specifications.

Unfortunately there appears to be no documented information on how much rod engagement into a coupling nut is required to achieve the strength of the rod or bolt being used with it. Coupling nuts are manufactured to the same ASTM specifications as regular hex nuts, and ASME B18.2.2 provides dimensional specifications for coupling nuts. Standard coupling nuts are 3 diameters in length. However, there is no reference to coupling nuts in the actual ASTM A563 or A194 nut specifications.

Your first step is making sure that the ASTM grade of coupling nut being used with the threaded rod or bolt is the same grade as the recommended grade of nut that would be used with the rod or bolt. For example, ASTM A193 B7 rods or bolts require an ASTM A194 2H heavy hex nut, so if you were to use a coupling nut with an ASTM A193 B7 rod, the grade of coupling nut should also be ASTM A194 2H. Although the amount of thread engagement is not specified, our coupling nut supplier recommends the bolt or rod should be threaded a minimum of one diameter in length into one end of the coupling nut.

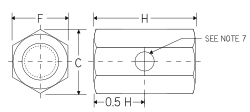

There may be an application which requires that the threaded parts going in each end of the coupling nut are engaged approximately one half of the coupling nut thickness. In this case, a hole may be drilled in the middle of one side of the coupling nut. This aids in the visual inspection to ensure that both rod ends are in fact meeting in the middle, not off center. According to IFI-128, note 7, the hole should be located at mid nut thickness and have a diameter of 0.2 to 0.4 times nominal nut size for sizes 2-1/2″ and smaller. For sizes 2-3/4″ and larger, the hole is 1″. Coupling nuts are manufactured without this hole unless otherwise specified.

As long as the correct grade of coupling nut is used and the bolts or rods are engaged a minimum of one diameter, the bolt should theoretically break before the threads strip. Again, this is only a common rule of thumb and we have no documented specifications that cover this issue. In any situation involving coupling nuts, we would recommend consulting with the engineer of record or a structural engineer to determine the appropriate length of coupling nut and amount of thread engagement required.

Thank you for this great article!

I fully understand the concept behind the thread engagement lengths on couplers.

What I am interested in is the tensile load-deformation behaviour of couplers. In most cases, they are used for tension relevant applications. Are there test standards that qualify the axial ductility of the couplers and how compatible they are to the corresponding threaded rods that are screwed in to them? In other words, are they rated for specific ultimate tensile strengths and yield strengths in the same as bolts and threaded rods?

Thank you in advance.

@Ramil- As far as we know, that are not any standards that specifically cover coupling nuts. We typically have our couplers made to the same chemical and mechanical requirements as regular nuts. So from that standpoint, they are tested to the same loads as a regular nut of the same grade, but there aren’t any coupling nut load ratings.

We have a bulkhead project that requires 27′ long galv 1 1/4 tie backs with 12″ threaded ends ,hillside washers on both ends and heavy hex nuts , need a quanity of 21 please quote need delivery by 5 /20 at latest , let me know if interested

@Rich- One of our salespeople will contact you shortly.

I need six pieces of 1/2 inch threaded pod couplers. They should be 4″ long. Can you let me know what the cost would be and soon I can have them. Thank you Please reply

@Stuart – I’d need a bit more information about what a ‘pod’ coupler is. We do not stock any 1/2″ standard couplers that long, but could specially manufacture them. If you’d like to contact our sales department with more information, we’d be happy to look into it.

What is the largest coupler aviaible length

@Stuart – The largest we stock in our facility is 1-8 x 3. However, larger sizes can be easily brought in or made to order.

Hey Anthony,

Thanks for the awesome article. This explains everything I was curious about regarding coupling nut length.

I have a quick question for you:

Is it possible to couple A449 galvanized rod to plain steel rod? If so, do you need a customized A563 coupling nut?

For a continuous hold-down shear wall, I’d like to use galvanized rod only for the segment embedded in a concrete footing, then couple it to plain steel rod above the mud sill. The plain steel segment would then extend upward about 7 feet into the shear wall.

However, since the galvanized rod has a slightly larger diameter because of the coating, I’m curious if there is a coupling nut that is half oversized for galvanized rod and half standard for plain steel rod?

Thanks,

Mike

415-696-6323

@Mike – Yes, it is possible to get a coupler like that. It would be a special, but it shouldn’t be too hard to make. We’d simply galvanize the whole thing, and tap out one end oversize for the galvanized rod, and tap out the other end standard, for the plain end rod. We done similar things before. If you want to let us know the details, we’d be happy to quote it. We can supply the A449 all thread as well.

Regarding hot dip galvanized threaded rod, nuts, and couplings. It appears to me that the rod and percentage of thread are slightly reduced to accommodate a 0.0017 coating,,,,, or not? If not, the hot-dipped nuts are bored and threaded slightly larger, to accommodate that 0.0017 zinc coating.

So, particularly if any reduction is made to the rod or bolt, some reduction of strength would occur, BUT, even if the male threaded steel piece is not reduced, the thread engagement will reduce if the female thread has an allowance for 0.0017 OR 0.0034 (.0017×2) of zinc, AND (obviously) the strength of zinc is substantially lower than steel,,,,, so, the pullout strength must be substantially lower for an assembly of hot-dipped components. I’m curious, but I’d guess that percentage of thread on typical “all thread” is relatively low,,, and as you might guess, I’m questioning the capacity of some of my installed and planned assemblies.

Any thoughts of info?

@Gary- You are correct that the capacity of galvanized, overtapped nuts is slightly less that their plain finish counterparts. However, the amount that they are tapped oversize does not reduce their tensile capacity below that of the mating rod, so the ultimate tensile strength of the assembly is not compromised. The root of the thread of the rod is still the weakest part of the assembly.