This question was submitted by a Port Authority on the East Coast. Anchor bolts were supplied by another company claiming they met or exceeded the requirements of F1554 grade 36. As it turns out, they did not.

Hi Greg,

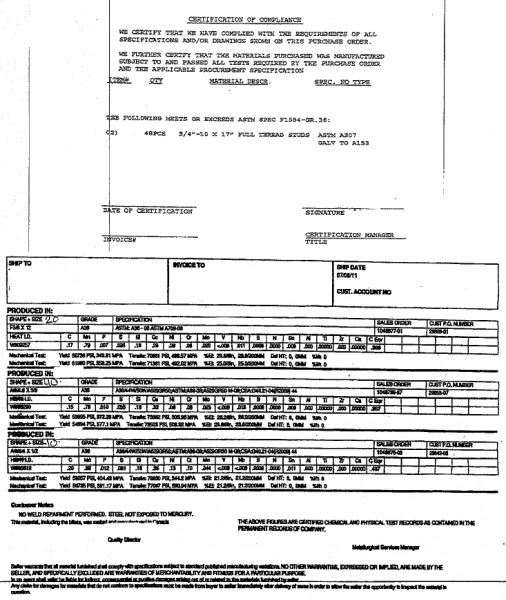

Sorry for being late to send you a clear copy of the Mill certification. Just to refresh your memory: The question is, ASTM F1554 Gr 36 against ASTM A307 also Grade 36. As you know, the contractor submitted ASTM A307 with the attached mill certification and stated that it meets or exceeds ASTM F1554.

First: What is ASTM F1554 … is this material ?? or just testing method ??

Second: Attached is a clearer copy for the Mill Certification.

Yield is 50,736 PSI

Tensile is 70,961 PSI

% elongation is 23.6 % to 25 % per 8 inches

What do you think ?? Are we missing any information in the mill certification for the F1554 – see attached – is the provided information in the mill certification can be passed as ASTM F1554?Thank you for your help

To address your first question:

ASTM A36 is a steel grade, not a bolt specification. It covers the raw material (in this case steel round bar) that is used to manufacture the bolts. A307 and F1554 grade 36 are ASTM specifications covering bolts. Both A307 and F1554 grade 36 bolts are frequently manufactured using A36 steel. ASTM A307 is a specification that covers mild steel bolts. There are two grades within the ASTM specification. A307 grade A covers bolts for general applications, while A307 grade B covers heavy hex bolts and studs for cast iron flanges. There used to be an A307 grade C specification covering anchor bolts, but it was eliminated in 2007 and subsequently replaced by F1554 grade 36.

Both A307 grade C (when it existed) and F1554 grade 36 have chemical and mechanical (strength) requirements that must be met in order to certify the bolts to these specifications. As you can see in the table below, F1554 grade 36 requires additional testing (reduction of area) that A307 grade C did not require.

Mechanical Requirements

| Grade | Tensile, ksi | Yield, ksi min | Elongation % min | Reduction of Area % min |

|---|---|---|---|---|

| A307 grade C | 58 - 80 | 36 | 23 | no requirement |

| F1554 grade 36 | 58 - 80 | 36 | 23 | 40 |

As for the bolts that were supplied…

One of the requirements of F1554 grade 36 is that the Reduction of Area of the steel must exceed 40%. For the anchor bolts in question, either this test was never performed or the data was never recorded on the test report. Most likely, the test was not performed since this is only a test of F1554 and not a test required of A307. Since this value is missing, there is no way to determine whether or not the bolts that were supplied (and are already in the foundation) have enough ductility (as determined by the Reduction of Area test) to meet the requirements of F1554 grade 36. There is a very good chance that the bolts would meet this requirement if they were tested, but they never were. Therefore, based on the test reports that accompanied the bolts that were supplied, these anchor bolts do not meet all of the requirements of F1554 grade 36. Tensile, yield, and elongation are all good, but the reduction of area requirement has not been met.

Many companies attempt to substitute A307 anchor bolts for F1554 grade 36 anchor bolts as has occurred in this case. The bottom line is that these anchor bolts that were supplied are missing data that is required to certify them to F1554 grade 36.

can we consider ASTM A36 Gr B material specification with fastener material F1554gr 36 both are the same

@Shahid- There isn’t a grade B within A36, in fact there aren’t any subgrades within A36. That said, A36 is a raw material standard whereas F1554g36 is a finished fastener standard. There are many similarities both chemically and mechanically, but since one is steel and the other a fastener, there are testing and dimensional differences between the two. You’d need to consult the MTRs for the steel to see if it meets the requirements of F1554, otherwise additional testing may need to be performed.

Thank you for this feed. It was very enlightening for me. Especially as a last minute reference. I had a situation today . And this pulled me thru.

I am a fabricators inspector. And very cautious about signing off unless I have facts.

Thank you so much Dane.

Hi Eduardo

We requested that ASTM-F1554-GRADE36 be used in a project

What is the best material to replace with the same mechanical properties?

Thanks

@Vahid- There are several mild steel grades that are similar to F1554g36, but none that are exact. Any material substitutions should be run past the project engineer.

What would be the material equivalency to manufacture F1554 Grade 55 bolts form raw material?

@Dan- the ASTM F1554 grade 55 chemical requirements are fairly loose, so most any low carbon steel that meets the mechanical requirements will likely meet F1554. That said, most manufacturers like ourselves have the steel rolled at the mill to specifically to meet F1554.

PARA FABRICAR PERNOS DE ANCLAJE BAJO F1554 GR 36

ES UTILIZADO ACERO SAE 1026

ASTM F1554 cubre los pernos de anclaje que están diseñados para ser empotrados en concreto para sujetar soportes estructurales a la base de concreto. Estos pernos de anclaje están disponibles en los siguientes

Grado 36,

Grado 55

Grado 105;

El número después del grado designa el límite elástico mínimo del sujetador (medido en ksi).

@Jose- Thank you for your comment. 1026 steel can be used to make grade 36 bolts, but it is only one of many steels that can be used.

I have an anchor consisting of 4 bars (7/8 ″) A307 welded to the base plate (1 ″) of a column (these bars in turn have a 70x70x19 plate welded at its lower end.

1. Can these A307 bars be welded to the plates, or must they be threaded?

2. Can I directly replace the A307 bars with A36 bars? If so, should the diameter be modified?

@Joe- Assuming your base plate is also a weldable material, we see no reason why you shouldn’t be able to weld the bars to the base plates. The mechanical requirements for A307 and A36 are almost identical, so a substitution shouldn’t be an issue, although as with all substitutions, we always recommend talking to the project engineer first.