Kailey's FAQs

Anchor bolts for light poles are configured in several ways. Ordering them can often be confusing and this FAQ will attempt to simplify that process. Light poles each have specific designs and the anchor bolts are designed to the exact specifications of each light pole to match the strength properties and pullout resistance needed to... Read more

The ASTM A307 specification does not provide any washer recommendations to go with fasteners specified to A307 grades A or B. Most commonly, a simple F844 flat washer is used with A307 fasteners. F844 washers have a larger outside diameter than F436 hardened washers. Since the A307 specification doesn’t recommend what to use, any washer... Read more

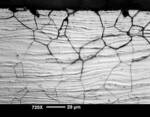

In order to answer this question, we must first define what intergranular corrosion is. It is a type of corrosion where the grain boundaries of crystallites in austenitic steel are more susceptible to corrosion than the inside of the material. Grain boundaries can become depleted during the manufacturing of stainless steel round bar, the hot... Read more

A325 and A193B7 bolts are among the most common, mass-produced bolts available in the marketplace. It is a common misconception that these bolts are interchangeable since they have a lot of similarities in their configurations, and both are considered high-strength bolts. In fact, these bolts have two very different applications and have differences in their... Read more

The A320 Grade L7M is a variation of the A320 Grade L7 specification used in low-temperature, low-pressure applications. Nowhere in the A230 specification does it discuss whether or not A320L7M fasteners can be galvanized. In theory, there is nothing preventing someone from galvanizing the material, however, the L7M designation comes from heat treating being the... Read more

Per ASME B1.1, threaded rods should be made at a 60 degree top angle. This is a standard that is produced throughout the United States, however, in recent years, Chinese manufacturers have figured out a way to save on steel costs by manufacturing threaded rods with 45 or 50 degree angles. This material does not... Read more

There are many differences between these two specifications. In order to understand these dissimilarities there are overviews of each specification below followed by a short summary of these variances. For the purposes of this FAQ we will be focusing on A193 Grades B8 (Type 304) and B8M (Type 316) versus F593 Alloy Group 1 (Type... Read more

A jam nut is a thin nut primarily used as a locking device, run up against a full-height nut that has been tightened into place to prevent that primary nut from loosening. Jam nuts are not used as structural parts and are commonly not manufactured to meet any specific nut specification since their primary function... Read more

A193 Grade B7M is a grade variation of the common A193 Grade B7 used in high-temperature, high-pressure applications. Nowhere in the A193 specification does it discuss whether or not A193B7M fasteners can be galvanized. In theory, there is nothing preventing someone from galvanizing the material, however, the application in which these bolts are intended to... Read more

At Portland Bolt we often receive requests for metric dimensioned products and our response is always the same. We do not have the capabilities to manufacture bolts or fasteners with metric diameters. The reason behind this is that all of our equipment and tooling is specific to the imperial (inch) system which is the measuring system... Read more