Unfortunately there appears to be no documented information on how much rod engagement into a coupling nut is required to achieve the strength of the rod or bolt being used with it. Coupling nuts are manufactured to the same ASTM specifications as regular hex nuts, and ASME B18.2.2 provides dimensional specifications for coupling nuts. Standard coupling nuts are 3 diameters in length. However, there is no reference to coupling nuts in the actual ASTM A563 or A194 nut specifications.

Unfortunately there appears to be no documented information on how much rod engagement into a coupling nut is required to achieve the strength of the rod or bolt being used with it. Coupling nuts are manufactured to the same ASTM specifications as regular hex nuts, and ASME B18.2.2 provides dimensional specifications for coupling nuts. Standard coupling nuts are 3 diameters in length. However, there is no reference to coupling nuts in the actual ASTM A563 or A194 nut specifications.

Your first step is making sure that the ASTM grade of coupling nut being used with the threaded rod or bolt is the same grade as the recommended grade of nut that would be used with the rod or bolt. For example, ASTM A193 B7 rods or bolts require an ASTM A194 2H heavy hex nut, so if you were to use a coupling nut with an ASTM A193 B7 rod, the grade of coupling nut should also be ASTM A194 2H. Although the amount of thread engagement is not specified, our coupling nut supplier recommends the bolt or rod should be threaded a minimum of one diameter in length into one end of the coupling nut.

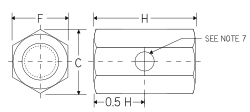

There may be an application which requires that the threaded parts going in each end of the coupling nut are engaged approximately one half of the coupling nut thickness. In this case, a hole may be drilled in the middle of one side of the coupling nut. This aids in the visual inspection to ensure that both rod ends are in fact meeting in the middle, not off center. According to IFI-128, note 7, the hole should be located at mid nut thickness and have a diameter of 0.2 to 0.4 times nominal nut size for sizes 2-1/2″ and smaller. For sizes 2-3/4″ and larger, the hole is 1″. Coupling nuts are manufactured without this hole unless otherwise specified.

As long as the correct grade of coupling nut is used and the bolts or rods are engaged a minimum of one diameter, the bolt should theoretically break before the threads strip. Again, this is only a common rule of thumb and we have no documented specifications that cover this issue. In any situation involving coupling nuts, we would recommend consulting with the engineer of record or a structural engineer to determine the appropriate length of coupling nut and amount of thread engagement required.

Hi,

A hanging bolt which has 2.5 MT load and required coupling nut as well to extent the length.how i can calculate the required minimum bolt size and coupling nut length?

@Lubna- Apologies, but we are unable to calculate those values for you. You will have to consult an engineer.

Is it possible for the coupling nuts to loosen off due to vibrations/elongation in the rod. Are there any specifications or vibration tests available that indicate if this is an issue with using coupling nuts. We are looking at using them for brace rods in crane buildings. We don’t want to specify tack welding as rods are galvanized. Also concerned with inducing fatigue cracks from the tack welding.

@Dennis- If vibration is a concern, and welding is not preferred, we are able to peen a thread, or that can be done in the field. By damaging a thread on one end or the other of the coupler, you are able to keep the coupler from backing off too far. You can also look at liquid thread lockers. We don’t have a lot of experience with those, but we know there are many types. As for a test or specification for vibration, we are not aware of anything.

I would like to use coupling nut to extend column anchor bolt. The coupling nut will be installed below column base plate ( existing anchor bolt dia. 1 3/8″). Is coupling nut the right application in this case?

After coupling nut and column base plate are installed, once it comes to tighten the nut with torque wrench, how could we control some relative motion/twist at the coupling nut?

@Nat- The coupler is a common fix for this problem, but we are unable to make any outright recommendations for your specific application. As for how to keep the coupler from rotating, you could try a tack weld if the situation allows.

Can I use coupler nuts to extend a 56mm diameter anchor bolt (8 nos) for a 20m high structure? The bolts were wrongly installed at 150mm above concrete and we need at least 500mm above concrete. Zinc plated A193 grade B7 bolts were installed.

@Isaac- Using a coupler to extend a base is a common method, however you will need to check with your project engineer to determine if it is the best method for your application.

I have a 3/8 threaded rod and trying to use a coupler to extend the rod. Is a 1/1/8″ Coupler sufficient for the attachment? Also does the length of a coupler increase the strength? or is the grade of material?

@Joseph- Couplers lengths are typically three times the diameter, so a 3/8″ diameter coupler should be 1-1/8″ long, and that is sufficient for general purpose applications. If your application requires something stronger, a higher grade is typically supplied. Increasing a coupler’s length does not increase it’s capacity.