What end types are available for bolts and rods?

You can watch a video covering four of these point types: the chamfer, semi-cone, chisel, and 45-degree angle cut.

Saw cut end

When a large diameter or small quantity of bolts is required, Portland Bolt will saw cut the steel round bar to create the cut lengths for the finished fastener. A saw cut end is smooth and free of any deformities, but is a time consuming labor process.

Product examples with saw cut ends:

- Anchor rods

- Anchor bolts

- Headed bolts

- Unfinished hardware

- Drift pins

- Swedged rods

Sheared end

Product examples with sheared ends:A sheared end is produced by a mechanical guillotine-like cutting process in which round bar is chopped, rather than cut. Shearing is a much faster and more cost effective process in comparison to saw cutting, especially for large quantities of parts. Due to the pressure of the process, the end of the round bar may have a small deformity at the cut end. This small lip and slightly oval end is typically removed when the bolt is threaded or chamfered, and only in a few instances will the finished product have a sheared end. Portland Bolt shears round bar up to 2″ in diameter and up to 100″ in length.

- Drift pins

- Sheared round bar

- Barrier pins

- Swedged rods

- Rods with thread each end

- Rods with thread one end

Chamfer

A chamfer is a conical surface at the starting end of the thread. A grinding process removes the first thread of the fastener to create a bolt that will easily accept a nut. The first thread can be easily damaged in packaging, shipping, or general handling in the field and by removing it, the manufacturer ensures the fit of the nut. Most imported and mass produced fasteners are chamfered. Portland Bolt chamfers virtually all galvanized bolts to eliminate the possibility of the first thread becoming damaged during the galvanizing process. However, galvanized bolts with rolled thread do not need to be chamfered since the roll threading process naturally creates a rounded end that is work hardened and resistant to deformities and damage.

- All thread rod

- Galvanized hardware

- Anchor bolts

- Anchor rods

- Headed bolts

- Cut threaded product

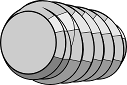

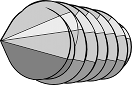

Semi-cone point

A semi-cone point describes an end that is similar to a chamfer, but has more material removed. Think of a semi-cone point as a “half point”. In the case of a semi-cone point, the material has been removed at either a 45 or 60 degree angle to about a length equal to the diameter of the bolt. Bolts with semi-cone points are very common in the pole line industry, allowing long bolts to be more easily installed in wooden poles and crossarms. Lag bolts that must be custom made due to their large diameter, length, domestic requirement, or nonstandard thread length are also a bolt that has a semi-cone point. Since large diameter lag bolts must be installed in pre-drilled pilot holes, they do not need a threaded point (gimlet point) or a cone point (full point) to physically displace the wood. Instead, custom lag screws are manufactured with a semi-cone point to allow the bolt to be inserted and threaded into a pilot hole. Semi-cone points are often used on drift pins, highway median barrier base pins, timber spikes and other pins that are being pushed through a material like wood, asphalt or soil.

- Pole line hardware

- Crossarm bolts

- Double arming bolts

- Lag screws

- Washer head bolts

- Highway barrier base pins

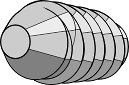

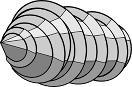

Cone point

A true cone point with a pointed tip is at times required for greater penetrating capability for drift pins and some other hardware. A full cone point, depending on diameter and size of the bolt, can be more labor intensive to produce. Often a semi-cone point is sufficient for the function of the bolt and often a cone point is unnecessary. In fact, “semi-cone point” and “cone point” are relative terms that should be defined before a fastener can be produced.

Gimlet point

A gimlet point is a threaded point on the tip of a lag bolt. They are necessary for small screws and lag bolts to displace the wood and physically drill a hole for the bolt itself. Common mass-produced lag bolts from 3/4″ diameter and smaller come with a gimlet point, but they are often unnecessary. Large diameter lag bolts must have a pilot hole drilled before the bolt can be installed. (See our pilot hole chart for lag bolts) A gimlet point is unnecessary for larger lag bolts since no wood will actually be displaced by the gimlet point since the drilling for the pilot hole has already removed the wood. Any lag bolt that Portland Bolt manufactures will not have a gimlet point, but will have a semi-cone point instead.

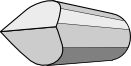

Chisel point

A chisel point is made with two 45 degree cuts forming a point at the end of the fastener. The vast majority of bolts that have these distinct points are lengths of all thread rod that are being embedded into already hardened concrete. The sharp point of the bolt is designed to break a capsule of epoxy at the bottom of a drilled hole, thus allowing the epoxy to fill the coat the all thread rod and bond the bolt to the concrete. Also some headed pins or unheaded pins being driven into soil or wood can use this point to facilitate the driving of the fastener.

- All thread rod used with epoxy

- Headed pins

- Unheaded pins

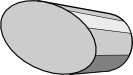

45 Degree Angle Cut

Much like the chisel point, the 45 degree angle cut has a primary purpose of breaking an epoxy capsule for an all thread epoxy anchor bolt. Instead of two 45 degree cuts, this point is made with one 45 degree cut that allows for more efficient use of material and due to the reduction in cuts allows less labor to be used in the creation of the bolt.

- All thread rod used with epoxy

- Headed pins

- Unheaded pins

Milled End

Portland Bolt has the ability to mill down portions of threaded rods to create a wrench flat. This flat or flats allows for a wrench to hold the rod in place to prevent it from turning or potentially to turn the rod itself. Since the milled portion reduces the diameter of the rod at the location of the flat or flats, Portland Bolt typically mills the very end of a rod since it should not affect the strength of the rod as opposed to milling the center of a rod where the tensile strength of the rod would be compromised. With our own manufacturing equipment, Portland Bolt can mill down the end of a rod with two wrench flats up to 1” diameter and with one flat up to roughly 2” diameter. When the end is milled, the fastener can no longer be marked with the grade or manufacture’s identifier due to the reduced surface area.

I’m looking for a stud like bolt 1/2 inch 20 length of min 3 inches no head round with a hole at the other ens like a c=clamp stile to insert a clevis pin through it 1/4 inch to 3/8 I dont know the name of it but I have a picture I can send if possible

@Noe- We are not familiar with that bolt, so yes, a photo would help us see if we can make your bolt.

This sounds like a proprietary Simpson Strong Tie design that is used primarily in residential construction. Traditional bent anchor bolts, headed anchor bolts, and anchor rods manufactured by Portland Bolt are used in heavy, industrial applications.

@Angel – Thanks for the great question. What you are describing sounds like a specific configuration of a bent bolt. As far as I am aware, there is no pointing process that creates a snake-like end. It sounds like an end of that type would be created by a bending process. If you have a photo or a drawing of the bolt, I might be able to provide you with some more information.

Greetings Kyle,

What is the name of the bolt that has a snake like end? Thank you.